diy injection molding machine arduino

We use mostly Sketchup for our modelingprototyping and have been in collaboration with our plastic molders from the beginning. The raw plastic material is first melted in the injection unit.

Microplast Options Desktop Injection Machine Youtube Injection Machine Plastic Injection Molding Diy Molding

In case of crush ribs you need to have a 025mm interference distance between the crush rib and the fitted part.

. Mostly PLCs are used for Automatic bottle filling machines but you can make a very basic and versatile bottle filler using an ArduinoYou can program the Arduino to automatically. Beyond that at right are typical prices for other auxiliary. We have other efforts in.

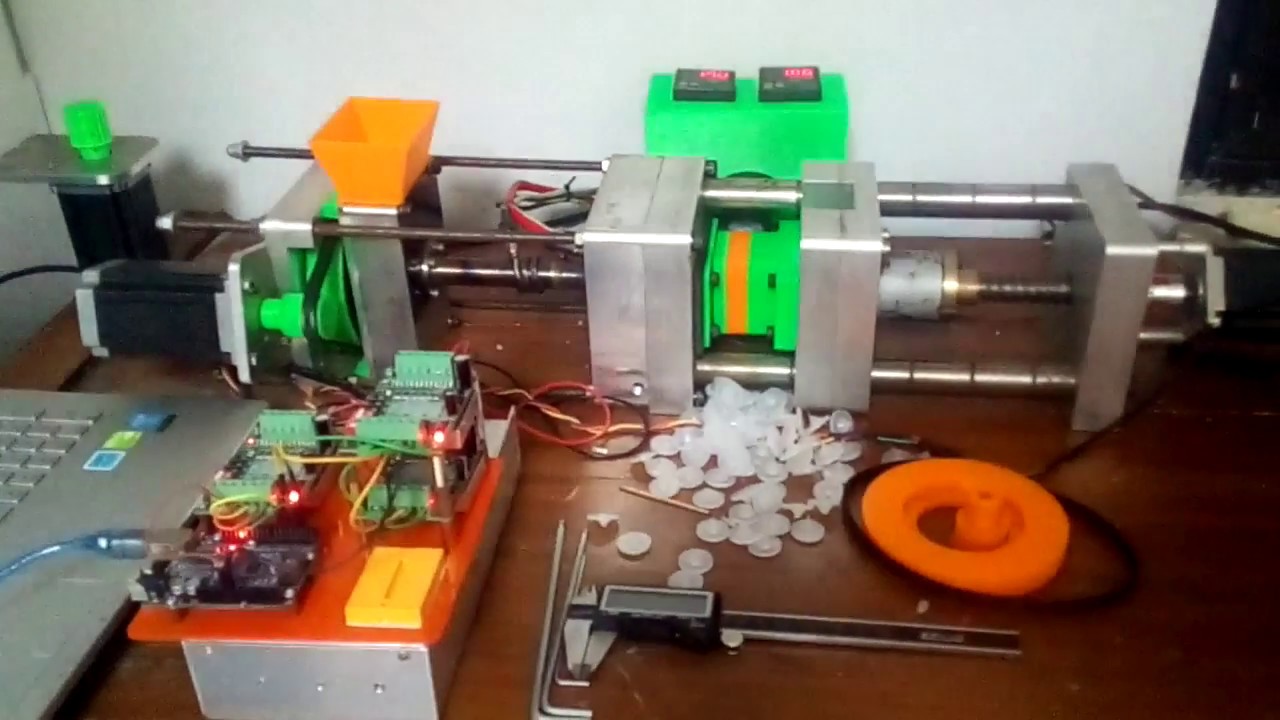

Controlled by arduino Uno AB Model AB-100 Plastic Injector Injection Page 736. On average injection molded parts should have a wall thickness that ranges from 008 2mm to 016 4mm but thin wall injection molding can go as thin as 002 05mm. Then the second motor should run the plastic for a set time press the plastic and stop slowly.

Injection moulding machine vector illustration. Read on to see the best DIY and desktop injection molding machines. Connect Arduino UNO board to your computer.

What is injection moldingThe injection molding process requires an injection molding machine raw plastic material and a machined mold. Eric May 282021 3495 views. I dont work hands on with the machines but I do the accounting.

Injection molding Vs Vacuum casting how to choose. Machine DIY Injection molding Hand Operated Injection Molding Machine 9100901029 Hand Operated Injection Moulding Machine Plastic Hand Moulding Machine Low Cost. Injection molding auxiliary equipment.

Adafruits Circuit Playground is jam-packed with LEDs. After uploading ArduinoISP sketch Please connect Arduino UNO Work as Master with the Arduino Nano Work as target using SPI bus. 131 Extrusion Blow Molding 132 Injection Blow Molding 133 Plant Considerations 134 Blow Molding Problems and Troubleshooting 135 Design for Blow Molding 136 Special Blow Molding Processes and Products Introduction.

We would test the STL on our 3D printers and then restart the. I work at an injection molding manufacturer. Injection molding Vacuum casting mold.

Due to the resemblance to the process of injecting fluids using a syringe this process is called injection molding. These machines use a conveyor belt which is an economical and fast way to fill bottles. We would make a concept piece send a rough out 3D model and they would put their touch on it clean it up with solidworks and then send us back an STL.

While 3D printing has now become easily accessible and cheap there are still several use cases where you need the advantages offered by injection molding even for. The raw plastic material is. Make sure you select the correct board name and serial port.

Injection molding is a forming process using molds. Machines cost in the hundreds of thousands and the aluminum molds can range from 20-120 thousand. Materials such as synthetic resins plastics are heated and melted and then sent to the mold where they are cooled to form the designed shape.

Injection molding machine and Equipment prices. LNS Technologies Model 150A. You also need a large power supply air compressor water cooling system.

In this video on Buster Beagle 3D Ryan shows how he made a tabletop injection molding machine for around 200. In this first effort we used plaster of the type they use in ceramics. DIY Electronics Arduino Hardware.

Be sure to check out the newest version of the machine called the MK3 herehttpsyoutubehw4NI60WW8IThis video will show you how to build your own. In the case of crush ribs however a draft angle is not needed. I am interested in the same machine.

Start Arduino program and from examples choose ArduinoISP sketch and upload it to the Arduino UNO board. But wall thickness also depends on the material used. The central material dryinghandling system including five insulated drying hoppers dehumidifying dryer pumps filters and conveying system would cost about 115000.

Make a Mold and Cast a Part. Snap joints should have a thickness of 05 times the wall thickness on the mold. While the effort did produce a good reproduction of the original the mold was destroyed in the process.

Stop breadboarding and soldering start making immediately. We designed and developed a homebuilt full. First a draft angle needs to be added in case of snap joints.

Using an off-the-shelf injection molding chamber by buster beagle 3D only a few standoffs and a support bracket needed machining in order to complete the mechanics. Automatic Bottle Filling Machines are most commonly used in beverages and soft drink industries. After building our DIY homemade CNC milling machine from scratch we wanted to push our home shop to the limits.

What is injection moldingThe injection molding process requires an injection molding machine raw plastic material and a machined mold. DIY Injection Molding Press. Then after some waiting time the process should be repeated.

A common PID controller. Finally we searched for a way to make a usable mold. This means shorter cycle times resulting in more parts produced per hour and lower production cost.

File Type PDF Manual Plastic Injection Machine Molding Machine Precious Plastics. After waiting for a set time period the first motor should open the mold while the second motor should retract slightly.

Bench Mounted Plastic Injection Moulding Machine Plastic Injection Plastic Moulding Plastic Injection Molding

Microplast Hot End Youtube Plastic Injection Molding Plastic Design Plastic Injection Moulding Machine

Desktop Injection Molding Machine Plastic Injection Molding Injection Machine Plastic Moulding

Wind Your Thread Automatically With This Arduino Powered Machine Arduino Blog Proyectos Electronicos Arduino Impresora 3d

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

The Pocket Inyector Desktop Plastic Injection Molding Machine Hits Kickstarter Plastic Injection Plastic Injection Moulding Machine Plastic Injection Molding

Homemade Plastic Injection Machine Injection Machine Plastic Injection Plastic Injection Moulding Machine

Introduction New Version Of Micro Injection Youtube Plastic Injection Molding Plastic Injection Injection Moulding

Youtube 3d Pechat Instrument Tokarnyj Stanok

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Injection Moulding Mould Design

Microinjection Molding Is Used To Manufacture Highly Valued Micro Medical Components Such As Sensors Plastic Injection Molding Mould Design Plastic Injection

Make Your Own Injection Molding Machine Make Diy Molding Plastic Injection Molding Epoxy Resin Crafts

Tabletop Injection Molding Machine Still A Big Hit Plastic Injection Moulding Machine Plastic Injection Molding Aluminum Molding

Pin By Thurin On Warhammer Casting Molding Molding Temperature Control Injection Moulding

Used Unused Rondol Technology Ltd Injection Molding Machine Diy Molding Plastic Injection Molding Plastic Injection

Home Made Injection Machine Injection Machine Injections Injection Moulding

Plastics Injection Moulding System Plastic Injection Molding Plastic Injection Injection Moulding

Goryachij Begun Lsr Holodnyj Begun Mikro Lite Pod Davleniem Enn Tong Indastrial Plastic Injection Molding Injection Machine Plastic Injection